Tem muita gente perguntando porque a UNDERDOG ainda não foi lançada, então a gente decidiu compartilhar os detalhes de seu desenvolvimento . Mas antes, queremos compartilhar um pouquinho da filosofia da RIVA e nossa motivação para o conceito da UNDERDOG.

A RIVA Cycles é uma marca que se propõe a fazer somente bikes urbanas duráveis, bonitas, coesas e de baixa manutenção.

A gente escolheu ligas de aço para nossas bikes por acreditar que é o material que faz mais sentido pra esse propósito. No início, até fizemos alguns protótipos em alumínio. E apesar de alguns ganhos estéticos, os resultados se mostraram sempre favoráveis ao uso do aço. Diferente do que espera o mercado de bikes urbanas, optamos pelo material que oferece mais conforto, durabilidade, segurança e que permite um melhor controle de qualidade.

Não é segredo pra ninguém que nossos framesets são produzidos na Asia. Uma das razões para que seja dessa forma, é que é quase impossível produzir bikes de Chromoly no país em função da falta de material disponível à preços razoáveis.

Talvez o que a maioria não saiba, é que todo o desenvolvimento é feito aqui. Desde a geometria, da especificação dos tubos e soldas, as simulações de tensões e fadiga em CAD e softwares de elementos finitos até a especificação dos componentes e preparação das tintas e acabamentos.

Com a Basement, nossa bike mais vendida, investimos 10 meses em seu desenvolvimento. Geometrias e componentes foram testados, simulados e compatibilizados. As Steampunks, por exemplo, demandaram ainda mais tempo, foram 14 meses desenvolvendo.

Outro aspecto importante da nossa filosofia é que a gente sempre acreditou na competição como ferramenta de desenvolvimento e aprendizado. E aqui o alumínio e o carbono passam a fazer sentido. Como uma marca urbana, encontramos no Criterium a possibilidade de desenvolver nossas bikes, testar novos materiais e gerar aprendizado.

SOBRE A UNDERDOG:

A partir de um prototipo pilotado pela Marina Richter, tivemos a oportunidade de entender a dinâmica de uma bike que precisa ser leve, rígida a ainda assim durável. Não é um processo fácil, nem rápido. A rigidez do alumínio, tão desejada em uma bike com o propósito de competição (ao contrário das bikes de uso diário), pode tornar a bike frágil e perigosa se não dimensionada e construída da maneira correta. O processo produtivo depende de várias etapas, como a soldagem (e sua preparação) e os tratamentos térmicos de solubilização e têmpera para garantir as propriedades da estrutura cristalina do material. Cada etapa precisa respeitar um controle de qualidade extremamente rigoroso, ou o resultado pode ser alguém seriamente machucado ou no mínimo uma bike pouco durável e com baixa performance. Controlar esse processo é complexo e caro.

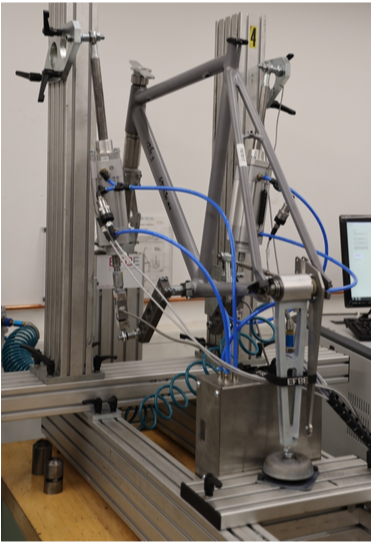

Para garantir que todos esses processos sejam feitos corretamente, uma série de normas e requisitos precisam ser atendidos. Usamos as normas EN 15194 e a última atualização da ISO 4210 para bikes Road & Race. Mas isso só não basta. É preciso testar o resultado. Os testes são realizados em Waldorf, na Alemanha, em um laboratório independente. E foi em um desses testes, no primeiro lote de produção da UNDERDOG que a gente encontrou uma pequena falha de projeto que nos fez voltar à prancheta.

Para garantir que todos esses processos sejam feitos corretamente, uma série de normas e requisitos precisam ser atendidos. Usamos as normas EN 15194 e a última atualização da ISO 4210 para bikes Road & Race. Mas isso só não basta. É preciso testar o resultado. Os testes são realizados em Waldorf, na Alemanha, em um laboratório independente. E foi em um desses testes, no primeiro lote de produção da UNDERDOG que a gente encontrou uma pequena falha de projeto que nos fez voltar à prancheta.

Segundo a norma, um quadro deve suportar 100 mil ciclos em diversos testes de fadiga, como força de pedalada, forças horizontais, forças verticais e cargas laterais. Além de testes de impacto e testes estáticos. Nosso quadro de alumínio da UNDERDOG passou com folga nos testes de forças horizontais, chegando a 150 mil ciclos sem sofrer qualquer dano assim como nos demais testes, mas falhou no teste de pedalada. Uma falha no desenho do chainstay, na depressão que acomoda a coroa (a depressão ficou muito agressiva), acabou por gerar um ponto de tensão que resultou na quebra (vide foto) aos 97 mil ciclos (so close!!).

Infelizmente, todo o lote, que já havia sido produzido, embalado e importado, será destruído. (salvaram-se os garfos de carbono). Sabemos o quanto é frustrante para quem estava esperando pelo quadro, mas safety first.

O lado bom é que vamos aproveitar para fazer pequenas melhorias no projeto, usando os dados dos testes, tornando o quadro ainda mais rígido e leve. O frameset da UNDERDOG vai demorar um pouquinho mais para chegar ao mercado, mas vai chegar ainda melhor.